You are here:Home> Products

Place of Origin:Shandong, China (Mainland)

Carbon Black Content:30%-50%

Carrier:PE/PP/EVA

Application:ABS/PS/PC/PP/PE

MFI(g/10min):0.1-80 (Can be customized)

Melting Point(℃):120-150

Density(g/m3):1.1-1.5

Moisture Content(less than %):0.15

Grain Diameter(mm):1.8-3.8

OIT(200℃):100-2000 min

Filler:CaCO3 or None

● Product Introduction:

Masterbatch is a solid additive for plastic used for coloring plastics (color masterbatch) or imparting other properties to plastics (additive masterbatch). Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to colour raw polymer economically during the plastics manufacturing process.

Anti aging black master batch is a kind of black master batch designed for geomembrane, drip irrigation tape, PE pipe. This product uses the high blackness, high brightness import carbon black, adding composite antioxidant and UV absorber, light stabilizer, prolong the service life of products.

1. Effect: high blackness, dispersed evenly, strong tinting strength.

2. Ratio of Dosage: Add anti aging black master batch products 5%,the products of oxidation induction period reached more than 100 minutes.

3. Application: Geomembrane , sun-shade net, drip irrigation belt, PE pipe, container bags, outdoor plastic products, etc

Functional Black Masterbatch |

|

Carbon Black Content |

30%-50% |

Carrier |

PE/PP/EVA |

Application |

ABS/PS/PC/PP/PE |

MFI(g/10min) |

0.1-80 (Can be customized) |

Melting Point(℃) |

120-150 |

Density(g/m3) |

1.1-1.5 |

Moisture Content(less than %) |

0.15 |

Grain Diameter(mm) |

1.8-3.8 |

OIT(200℃) |

100-2000 min |

Package |

25kgs Paper Bag |

Technical Specification |

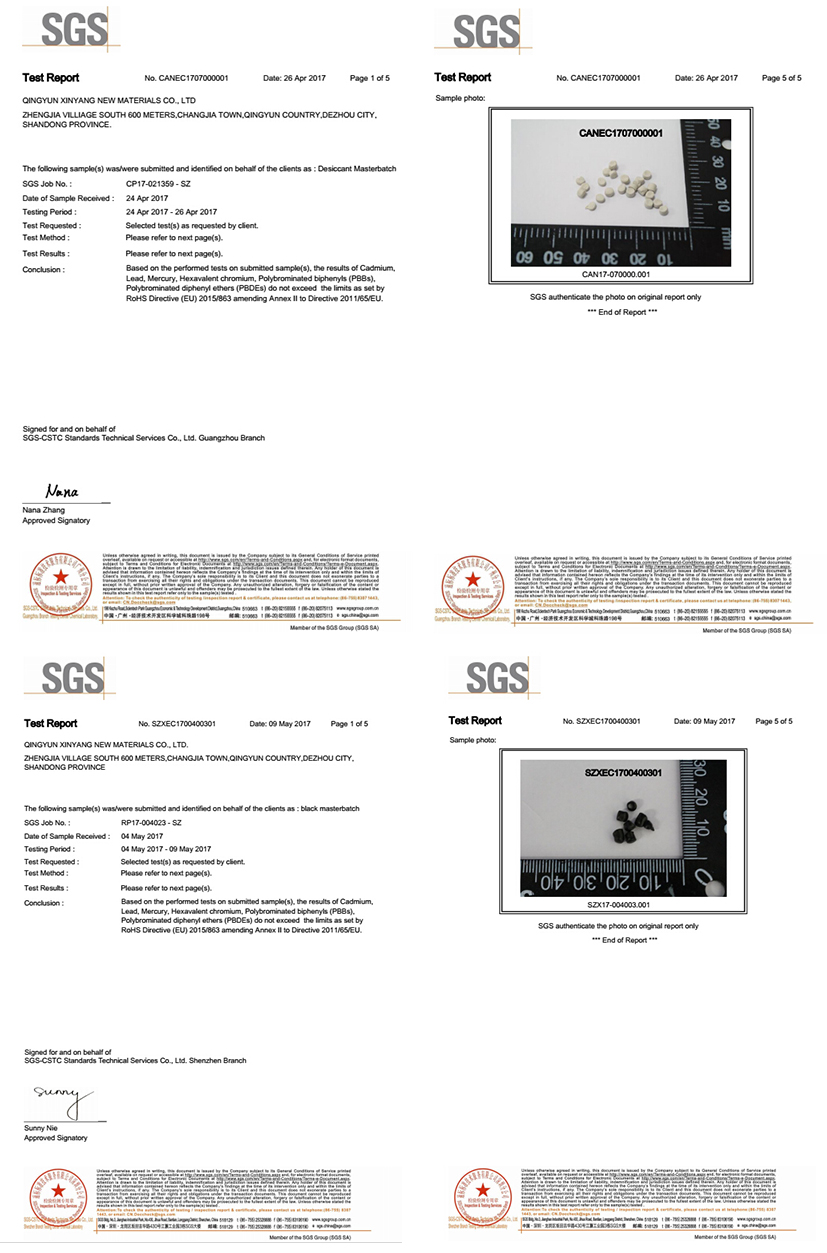

SGS Certificate |

Light Fastness |

Grade 4-8 |

Heat Resistance |

≥4 |

Migration Resistance |

≥4 |

Filler |

CaCO3 or None |

Add Ratio |

Recommend to add 2%-10% |

● Product Advantage :

1.Choose high quality carbon black with steady properties.

2.Use the organic toughening dispersant, processed and modified by special technology.

3.Good dispersion. The optimized dispersant help the carbon black to spread.

4.Good dyeing property, high brightness, high temperature resistance and good stability.

5.Conform with the International health standard.

6.The content of carbon black customized as customer’s requirements.

The advantage of Masterbatch is dust free, easy flowing, cheaper than compound cost and consumes very little warehouse space. The disadvantage of Masterbatch is that it has poorer uniformity of color.

● Product Application:

1.Fiber ( Carpet, Textiles, Upholstery, etc.)

2.Film ( shopping bags, casting film, multilayer film, etc.)

3.Blow Molding (Medical & Cosmetic container, Lubricant & Paint container, etc)

4.Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

5.Injection Molding (Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)

● OEM:

1.COLOUR MATCHING

Based on important datas, such as application process, base resin, desired letdown ratio, chemical resistance and heat resistance specifications, light fastness conditions with the type of end product exposure and food grade approval requirements from the customers etc

2.TECHNICAL SUPPORT

The manufacturing lines of the company are backed by state of the art testing and controlling facilities in a laboratory equipped for research and development work

3.AFTER-SALES SERVICE

● QC:

● FAQ:

Q1:Do we provide free sample of the products

A: Of course,please feel free to tell me your specific require,and then we will make the corresponding customized sample to you .

Q2: What is the shipping terms?

A:FOB Tianjin,others accepted

Q3: How about your payment?

A:T/T,L/C,western union.

Q4:What kind of plastic do our masterbatch fit?

A:Perfectlysuit:PE/PP/PC/ABS/PET/HIPS/GPPS/PA/PMMA/AS/POM/PU/TPE.

Q5. How to use masterbatch?

A: Simple for using, just mix up with the resin granules according to the dosage ratio under appropriate temperature.

Q6. The difference between the general use and the special purpose masterbatches?

1:Special purpose masterbatch: used as the same material as carrier. For example, ABS products often use master batches based on ABS.

2:General use masterbatch: Use one resin as carrier, but also can be used for coloring other resins.

In general, it’s easy to use this masterbatch but there are some shortcomings.

A. Poor predictability of the color.

The final color changes according to the change of resin.

B. Affect other characters of plastic products.

Especially the hardness of products for it’s easy to be deformed and distorted, especially for engineering plastic

C. Higher cost

General use masterbatches often use pigments which have higher heat resistance grade and higher cost.

● Packaging And Storage:

1.All the packing can be customized.

2.Paper plastic composite bag.

3.Plastic bags for inner packing, good quality moisture-proof bags for outer packing.

4.We generally make 1-2kgs per small bag by accurate weight, it will be very convenient for the customer using. It’s very easy to handle the dosage.

5.Net weight is 25kg/bag.

● Certifications:

● Factory:

Qingyun Xinyang plastic masterbatch Co. Ltd is founded in 2002, registered capital of 5 million, 50 million fixed assets, covers an area of 30 thousand square meters.

The company is located in northern Shandong, the hinterland of the Yellow River Delta, the southwest coast of the Bohai Bay, North Bohai, Tianjin port and Qingdao port adjacent to convenient transportation and smooth transportation.

Since the establishment of the company, the introduction of advanced management concepts, the company has formed an annual output of 20000 tons of black masterbatch, defoaming Masterbatch color masterbatch and white 10000 tons, 10000 tons, 5000 tons of polyethylene wax filled masterbatch, the production capacity of 4000 tons. Product sales, domestic and exported to the United States, Venezuela, South Africa, Saudi Arabia, Southeast Asia, the Middle East, Africa, Europe and many other countries and regions.

● Transport:

Provide EXW,FOB,DDP,DDU shipping terms.

● Payment:

Support T/T Deposit , Balance against bill of lading,Alibaba Trade Assurance ,Letter of Credit and other paymentterms.

● Contact Us:

Mr. Zhou

Tel:+86-0531-88995327

Address:Zhengjia Villiage South 600 meters,Changjia Town,Qingyun country,Dezhou City, Shandong Province.If you're in need of our products to help with your business, welcome to contact us. We are a professional manufacturer of various masterbatches, offering you the best quality products with good performance and competitive price.

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号