You are here:Home> Products

Specifications:ROHS SGS ISO9001-2008 EN-71

Safety Standard:Non-toxic and Food Grade

Plastic Carrier:PE/HIPS

Color Type:True/Semi-transparent/Fluorescent/Bright Yellow

Light Fastness Level:6

MFI:10~40, normally 25, up to your choice.

Application Methods:Injection Molding & Blow Film

Granule Length:3mm

Diameter of Granule:2.5mm

Moisture Content:Less than 0.15%

● Product Introduction:

The Newest Reliable Quality injection moulding colormasterbatch

What is Masterbatch ?

Masterbatch is a solid additive for plastic used for coloring plastics (Color Masterbatch) or imparting other properties to plastics (Additive Masterbatch). Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to color raw polymer economically during the plastics manufacturing process.

Technical Data Sheet |

||

Masterbatch Carrier |

Melting Point |

Heat Resistance |

LDPE |

105°C |

210°C |

LLDPE |

120°C |

210°C |

HDPE |

135°C |

210°C |

PP |

165°C |

220°C |

ABS |

170°C |

220°C |

GPPS |

185°C |

220°C |

PA6 |

220°C |

260°C |

PC |

230°C |

260°C |

PET |

230°C |

260°C |

HIPS |

270°C |

300°C |

PA66 |

270°C |

300°C |

Index |

||

Masterbatch Carrier Content |

15%~85% |

|

Pigment Content |

15%~50% |

|

Moisture Content |

≤ 0.15% |

|

Granule Diameter |

2.5mm |

|

Particle Size |

≤ 2 μm |

|

Density |

1.1g/cm³ |

|

MFI (g/10min) |

10~45 |

|

Weather/Light/Color Fastness |

Level 4~8 |

|

Color Migration Resistance |

Barely Dissolve Out |

|

Add Ratio |

2%~4% |

|

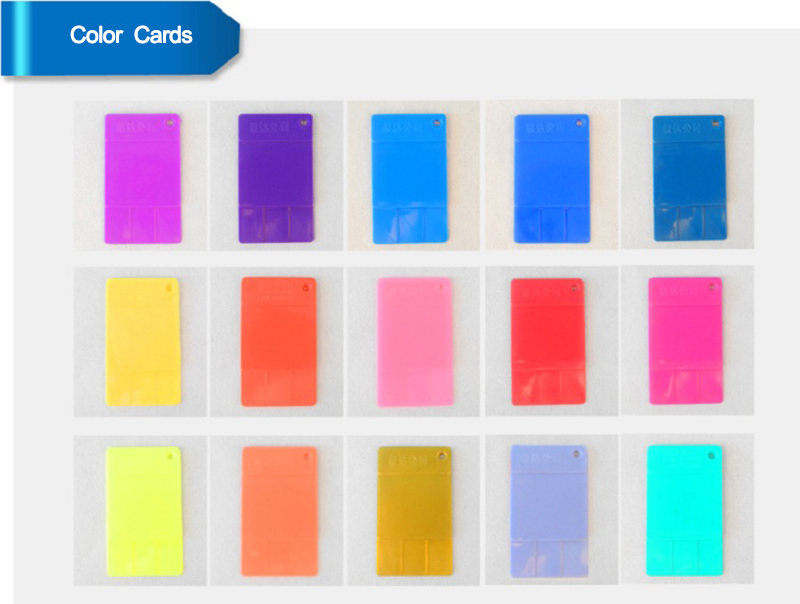

● Sample Display:

● Product Advantage :

A Complete Set of Advanced Detection Facilities

1. USA DATACOLOR and Japan Minolta Color Detector to to do colorimetric analysis.

2. Huawei ROHS Element Detector, to do heavy metal analysis.

3. Melt Flow Index Detector, to do melting rate analysis.

4. Pull Pressure Detector, to do flexibility analysis.

5. Impact Strength Detector, to do hardness analysis.

6. Blow Film Machine to test the plastic bags thickness, smooth and flexibility.

R&D Team and Quality Control System

1) Got 4 professional engineers in Research & Development Team.

2) R&D Team Leader has 22 years experience in Plastic Solution & Manufacture.

3) Masterbatch and Color Card as Client’s Sample or Pantone Chart Require.

4) Low Rate Initial Production.

5) Mass Rate Production after Production and Quality Datas are fine.

6) Regular Product Testing by authoritative Test Institutions.

● Product Application:

Automobile Parts/Toys/Building(Construction) Materials/Electronic Devices/Furniture/Household Objects/Home Appliances/Daily Use Commodities/Many Other Plastic Industry Products.

● Our service:

1 High quality and competitive price

2 Quick door to door service

3 Advanced testing equipment

4 Good after-sale service

● OEM:

1.COLOUR MATCHING

Based on important datas, such as application process, base resin, desired letdown ratio, chemical resistance and heat resistance specifications, light fastness conditions with the type of end product exposure and food grade approval requirements from the customers etc

2.TECHNICAL SUPPORT

The manufacturing lines of the company are backed by state of the art testing and controlling facilities in a laboratory equipped for research and development work

3.AFTER-SALES SERVICE

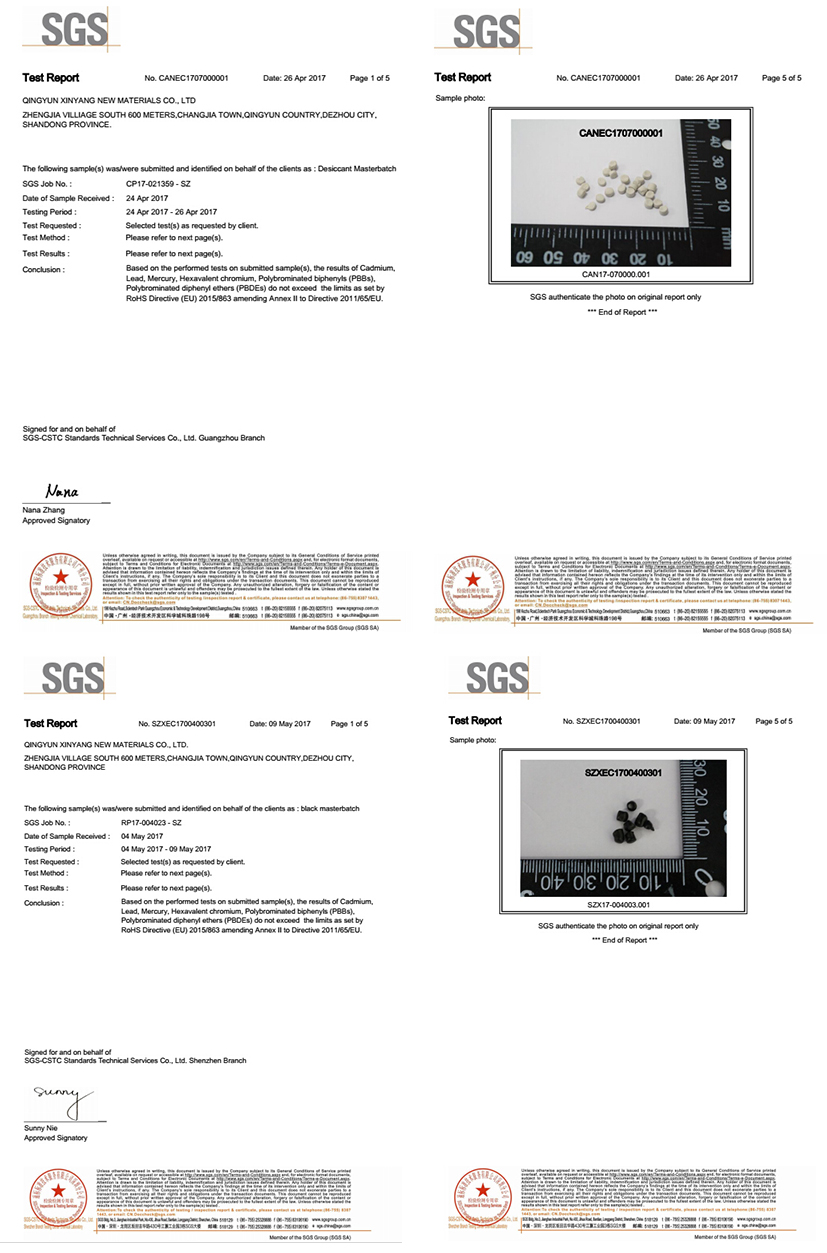

● QC:

● Color cards:

1. Great Compatibility and Fusion between Plastic Raw Material and Masterbatch, Color of Uniform Dispersion, No black spots/flow lines/marks/impurities show up under the sun light, High Flexibility, Micronization Particles, Smooth Surface, Beautiful and Glow Luster, Low Moisture Content, Low Rework Rate, Low Rejection Rate.

2. High Level Color Migration Resistance and Great Color/Light Fastness. (Color/Light Fastness: Level 4~8.)

3. High Heat Resistance. (Total Thermal Load/ Heat Fastness can reach 300℃/2min.)

4. Excellent Color Dispersion and High Concentration.

5. Great Weather Fastness/Ability/Resistance and Nearly No Color/Material Dissolve out during long time.

6. Virgin Plastic as Carrier: Non-toxic and Environmental Friendly.

7. Melt more faster, Efficient in Extrusion and Injection. (Normal Melt Flow Index from 10 to 45, Total can reach 130.)

8. Great Flexibility Performance and Impact Strength. (We got Pull Pressure Material Detector, Impact Strength Detector, as to maintain the flexibility performance and impact strength of every product.)

9. Extremely High Efficiency: Add 2%~3% in injection/extrusion, 3%~4% in blow molding/film. (We got a Blow Film Machine, an ABA Extrusion Machine and an Injection Machine, to test whether our masterbatch will perfectly apply to the client’s products or not.)

10. Processing Easily and Environmental Friendly, no more Ash or Dust problems.

11. Low Wastage, Beyond 97% Utilization Rate.

12. Consolidated Raw Material Suppliers: Sinopec/BASF/Exxon Mobil/Clariant/BAYER/Dupont.

13. Perfectly Suitable for: PE/PP/PC/ABS/PET/HIPS/GPPS/PA/PMMA/PVC/AS/POM/PU/TPE.

● Production Flow:

1. Personal Customization. (Please kindly feel relieved to tell us all your specific require, like:“Pantone Color Number/Polymer Carrier/Heat Fastness Level/Light Fastness Level/MFI/Pigment Concentration/Your Final Product Applications”, we will try our best to satisfy you.)

2. Fast Mass Producing, mass produce within 1 week.

● FAQ:

1. Do your precious Products need to protect from sunshine?

Indeed, if your precious products are using in the outdoor, we can add Anti-UV agent in the Masterbatch to make it more high Light/Color Fastness.

2. Do your precious Products need to be more white and get rid of bad smell?

Indeed, if your precious products are made of recycled plastics, we can add whiten agent or special fragrance agent in the Masterbatch to make it more white and get rid of bad smell.

3. Do your precious Products need to protect from static and raging fire?

Indeed, if your precious Products need to protect from static and raging fire, we can add Anti-static and Flame Retardant additive agent in the Masterbatch to make it's surface more cleaner, avoid dust in the air, and improve the Electronic Products safety level, avoid raging fire.

4. Why you should use Masterbatch with Virgin Plastic Carrier?

4.1) Due to Masterbatch is high pigment concentration material, so we need high quality virgin polymer carrier to make this compound, to ensure the excellent property and performance.

4.2) Virgin Polymer Carrier Masterbatch will dispersion better, especially in resisting high working temperature, but recycled plastic carrier is easier to cause Color Burn.

4.3) Virgin Polymer Carrier Masterbatch is much more safer to human health and much more friendly to environment.

5. Why you should use Masterbatch instead of Pigment Powder/Chemical Additives?

5.1) In many cases, it’s more economic to use Masterbatch when manufacturers are unfamiliar of combination between Pigment Powder/Chemical Additives and plastic raw materials, spend less trial time, make less waste materials and manpower in color matching.

5.2) Masterbatch is better dispersion than Pigment Powder/Chemical Additives.

5.3) Chemical Additive/Pigment stability will improve in Masterbatch, cause the polymer feature avoid moisture and oxygen from the air during storage and processing.

5.4) More easy and convenient to use, beyond 97% utilization rate, precise add ratio, ensure the production more productive.

5.5) Protect the health of operators from Pigment Powder/Chemical Additives, because they will easily floating in the air during the adding and mixing process.

5.6) More clean manufacture environment.

5.7) End Products will show properties more perfectly when applying Masterbatch, such as: flexibility/fragrance smell/glossiness; but using Pigment Powder/Chemical Additives will turn the End Products into fragile smell.

smell.

5.8) Melt more faster, efficient extrusion and injection.

5.9) High Efficiency, add 2%~3% in injection/extrusion, 3%~4% in blow molding/film.

6. Why choose Customized Masterbatch?

6.1) One kind of Color/Additive Masterbatch contains 1~8 kinds of pigment/additive, mixing and matching by professional polymer engineer, in proper proportion, some organic dye may conflict with inorganic dye, so are the additives.

6.2) Different kind of Polymer has different kind of physical property and chemical reaction, so are the Color/Additive Masterbatch.

6.3) If you insist cheap price General Use Masterbatch, it must lead some bad results, such as: poor compatibility and fusion between plastic raw material and masterbatch, uneven color dispersion, some black spots/flow lines/marks/impurities show up under the sun light, brittle, coarse particles, rough surface, no luster, dim, more moisture content, higher rework rate, higher rejection rate.

6.4) If you sincere desire to avoid these bad results above, you'd better use Customized Masterbatch.

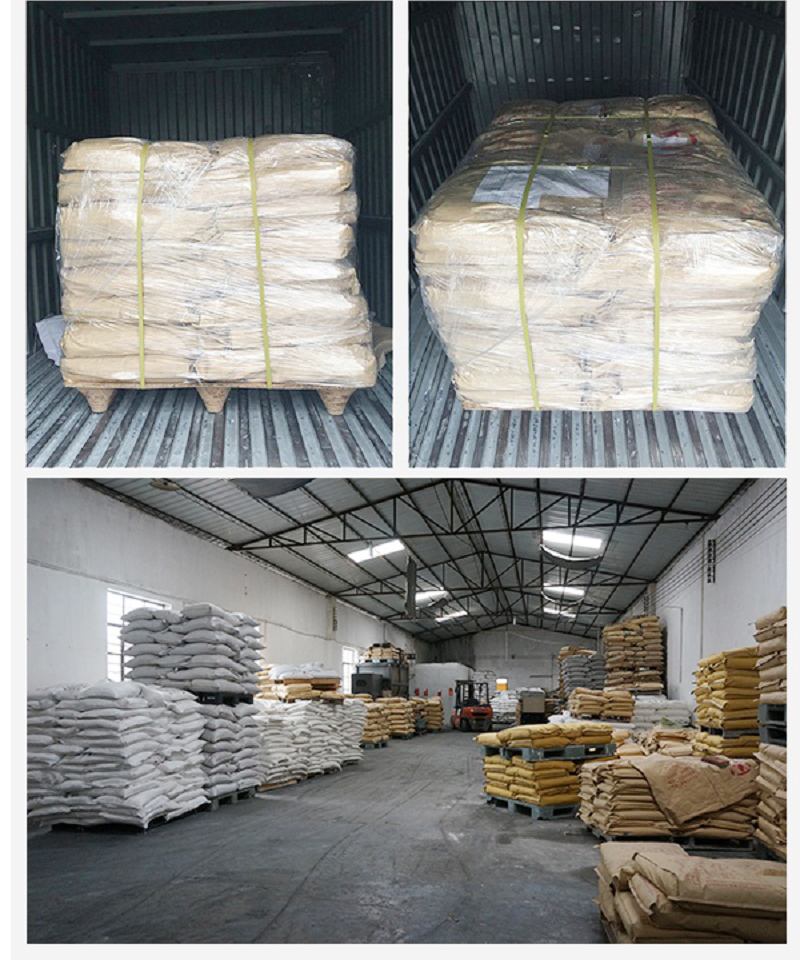

● Packaging And Storage:

1. Punctual Delivery, deliver in 20 days, delivery time must fit your processing needs after we made an intimate ally.

2. Flexible Shipping Terms: FOB, EXW, CFR, CIF, DOOR to DOOR.

3. Regular Packing: Waterproof Bag, 25 kg/bag.

4. Flexible Payment Terms: T/T, Western Union, L/C, D/P, D/A, Paypal.

Free Samples: Just tell us your specific require, and then we will make the corresponding customized samples to you.(No matter where you are, we will find you, and deliver the sample to you in 3~5 work days.)

● Certifications:

Got Certificates like: SGS/ROHS/EN-71/ISO9001-2008.

● Factory:

Qingyun Xinyang plastic masterbatch Co. Ltd is founded in 2002, registered capital of 5 million, 50 million fixed assets, covers an area of 30 thousand square meters.

The company is located in northern Shandong, the hinterland of the Yellow River Delta, the southwest coast of the Bohai Bay, North Bohai, Tianjin port and Qingdao port adjacent to convenient transportation and smooth transportation.

Since the establishment of the company, the introduction of advanced management concepts, the company has formed an annual output of 20000 tons of black masterbatch, defoaming Masterbatch color masterbatch and white 10000 tons, 10000 tons, 5000 tons of polyethylene wax filled masterbatch, the production capacity of 4000 tons. Product sales, domestic and exported to the United States, Venezuela, South Africa, Saudi Arabia, Southeast Asia, the Middle East, Africa, Europe and many other countries and regions.

● Transport:

Provide EXW,FOB,DDP,DDU shipping terms.

● Payment:

Support T/T Deposit , Balance against bill of lading,Alibaba Trade Assurance ,Letter of Credit and other paymentterms.Within 1 week after receiving whole payment.

● Contact Us:

Mr. Zhou

Tel:+86-0531-88995327

Address:Zhengjia Villiage South 600 meters,Changjia Town,Qingyun country,Dezhou City, Shandong Province.If you're in need of our products to help with your business, welcome to contact us. We are a professional manufacturer of various masterbatches, offering you the best quality products with good performance and competitive price.

Your satisfaction is our pursuit, we will spare no effort to try our best to serve you better!

Welcome to contact us and then make some business cases!

I am sure that we will become a stable and strong ally soon!

Just feel relieved to earn more market share and straight to the blueprint with us!

Send your message to this supplier

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号