Problem1: Striped pigment strips in the product under sunlight Considering both physical and mechanical properties of plastics and plastic molding processes: 1. The temperature of the injection molding equipment is not well controlled, and the color masterbatch cannot be thoroughly mixed with the resin after enteri....

Filler masterbatch: In the process of plastic processing, the pellets obtained by mixing various additives, fillers and a small amount of carrier resin are composed of carrier resin, filler and various additives. Performance and cost are primarily dependent on the carrier resin. The masterbatch is composed of carrie....

First, the dispersion is high Black masterbatch is produced using carbon black. High-load black masterbatches produced using single or double screw extruders have very poor dispersion. When the end user mixes or molds these black masterbatch, its performance is only slightly better than carbon black, but the effec....

First, the masterbatch with good stability should be selected. Some masterbatches have good coloring effect at that time, but after a while, fading and other phenomena will appear, which seriously affects the appearance and quality of plastic products. Second, to choose masterbatch easy to use, some masterbatches a....

There are three main reasons for the color difference of the masterbatch: Extrusion: The heat resistance of the toner is poor, and the color masterbatch must be low in temperature. Do not allow the material to stay in the extruder for a long time. The extruder die is clogged and the material in the barrel can also ....

Masterbatch (English name Masterbatches) full name plastic masterbatch, alias masterbatch is a plastic processing aid developed in the 1980s, it is composed of excess chemical additives, carrier resin and dispersant. The masterbatch is an aggregate obtained by uniformly superabsorbing a pigment (dye) in a resin. Mast....

The color masterbatch can be divided into: non-woven color masterbatch, chemical fiber color masterbatch, etc. Here, the difference between the universal color masterbatch and the special color masterbatch is introduced: Universal color masterbatch: A resin (often a low melting point PE) is also used as a carrier....

Masterbatch is also called color masterbatch. It is a new type of special colorant for polymer materials. Let's take a look at the composition of masterbatch: 1. Polyoxymethylene is 30-80 parts, one or two of copolymerized formaldehyde or homopolyformaldehyde, and the melting temperature is 190-230. 2. ....

1. Make the pigment more dispersible in the product In the production process of the color masterbatch, the pigment must be refined to improve the dispersibility and tinting strength of the pigment. The carrier of the special color masterbatch has the same plasticity as the product, and has good matching proper....

The carrier is a substance that carries carbon black. What kind of raw materials are used for general plastic products, and what raw materials are used for the carrier. The black masterbatch thus produced has good compatibility with the plastic raw material. For example, PS (polystyrene) plastic products, the black mas....

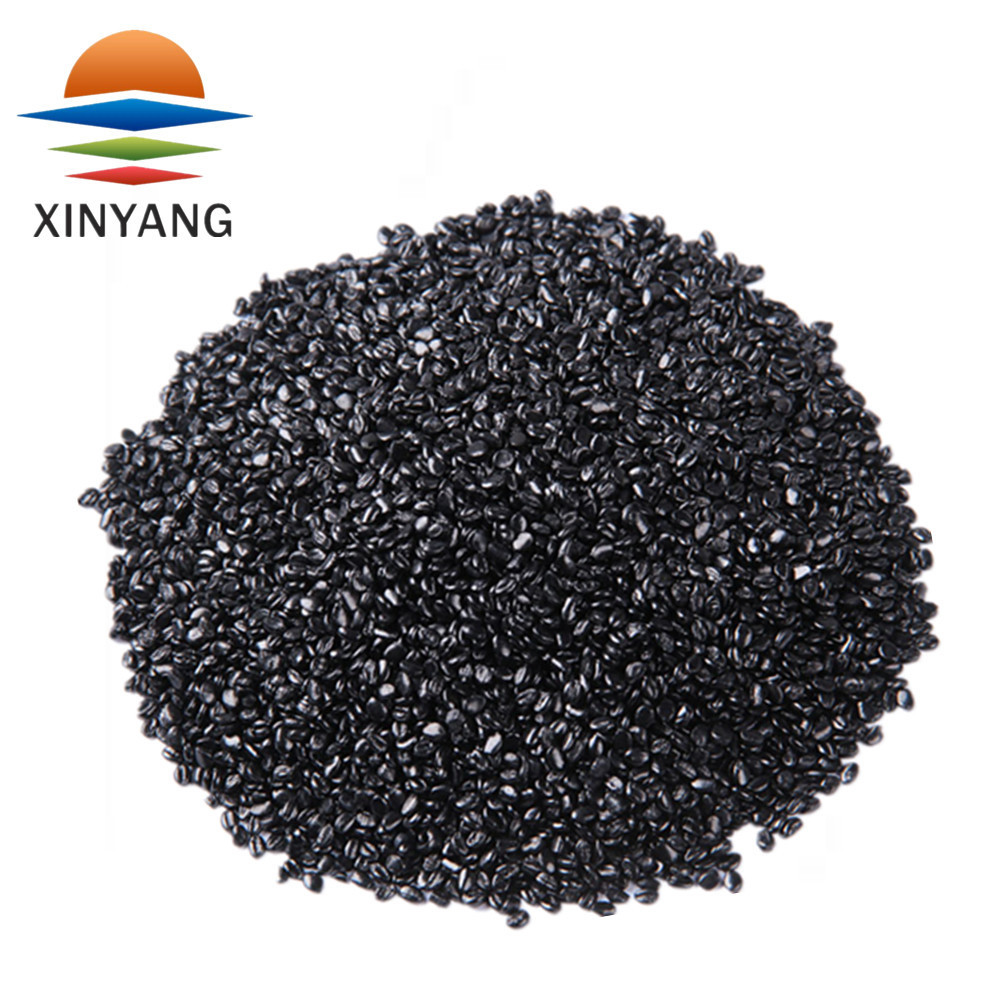

Appearance: 2.4*2.8mm black cylinder Scope of application: Suitable for most hot melt soft resin blown film, pipe, sheet, injection molding, granulation, phase dissolution in LDPE, LLDPE, HDPE, PP, PVC, PE copolymer and other plastic processes. Advantages: environmentally friendly, non-toxic, odorless, smoke....

1. black masterbatch appearance: 2.2 * 2.8 cylindrical black body. 2. black masterbatch adaptation range: Suitable for most thermal resin injection molding, pumping, pressing, film blowing, wire, pipe and other processes. 3. black masterbatch usage: mix with the raw materials to produce. 4. black masterbatch....

For the use of color masterbatch, the main process is to make different colorant preparation processes according to different color masterbatch, and at the same time, different functions can be realized, in which different development status is carried out. It is based on different development processes to get diff....

The quality of masterbatch depends mainly on the following five factors. 1. Dispersibility is better. 2. Strong coverage. 3. Liquidity is better. 4. Compatibility is better. 5. Stability should be consistent.....

Black masterbatch Applicable range: suitable for blown film without pitting, injection without pattern, and extrusion gloss. Black masterbatch polyolefins: HDPE, LDPE, LLDPE, PP, EVA, TPE, PVC, etc. Non-polyolefins: PET, PBT, PC, PA, ABS, AS, PS, POM, etc. Storage of black masterbatch: Store in a cool dr....

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号