Main technical indicators of white masterbatch 1. Resistance to migration (level) [≥4] 2. Moisture content (%) [≤0.30]8, total color difference [≤1.50] 3. Melting temperature (oC) [125 ~ 200] 4, white masterbatch dispersibility: [colorless dots, stripes] 5, light fastness (grade) [5-8] 6, ....

In the plastics industry, the common method to enhance the use of plastics is to add filler masterbatch. It is this large demand that has led to the widespread use of filler masterbatches. Not only in the plastics industry, but also in more industries. However, many companies find that the filler masterbatch often ....

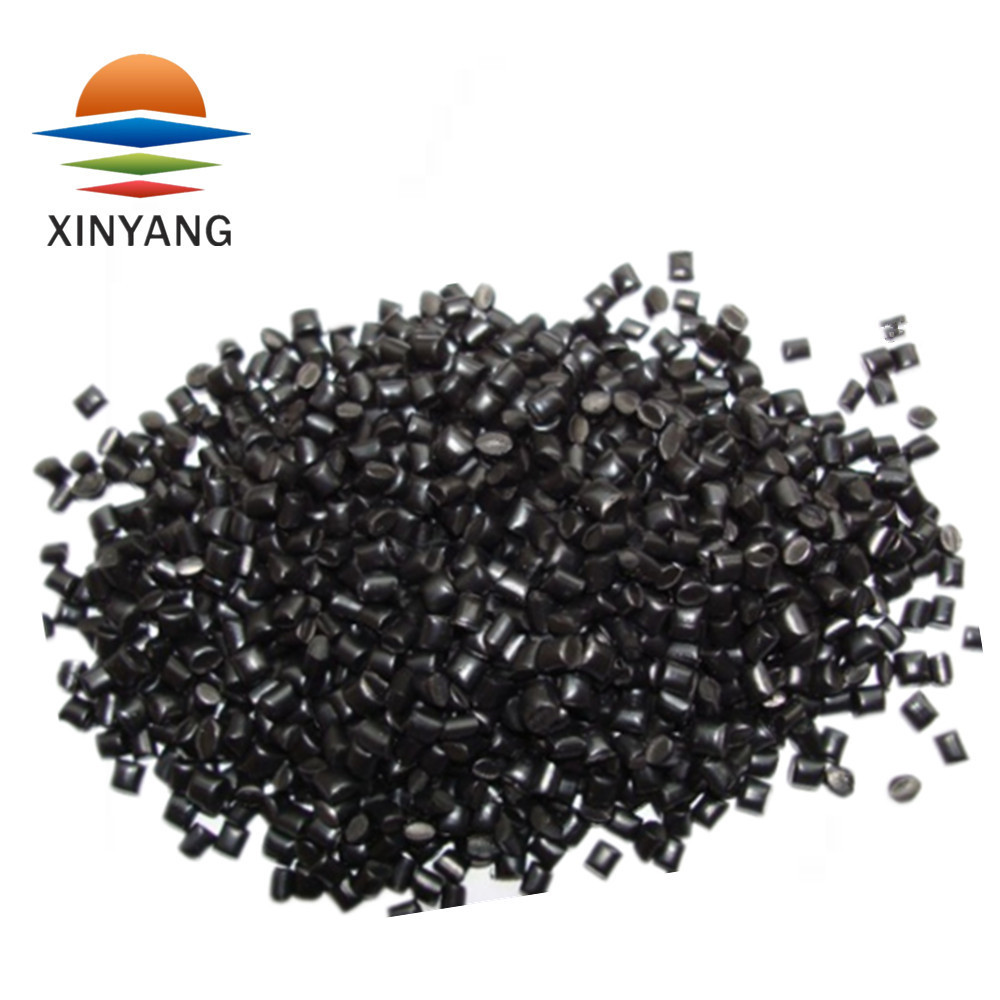

1. The black masterbatch is made of resin and high pigment carbon black. The carbon black concentration reaches 40%, the blackness brightness is also high, the temperature resistance is very good, the color masterbatch and the resin have good fusion degree, and the surface of the product will not be layered. In ord....

The commonly used masterbatch technology is a wet process. The masterbatch is made by aqueous phase grinding, phase inversion, water washing, drying and granulation. Only the quality of the product can be guaranteed. In addition, the pigment should be subjected to a series of masterbatch technology tests, such as d....

Filler masterbatch is an important material for the production of plastic products, which can enhance some properties of the product and improve its overall performance. There are many types of filler masterbatch, such as PP polypropylene filler masterbatch, injection molding masterbatch, blown filler masterba....

The masterbatch is mainly used in plastic products. Different masterbatch has different effects. What effect does it have on filling the masterbatch today? Some of the masterbatch we mentioned earlier mainly play a leading role in the color of the product. What effect does it have on filling the masterbatch? We are e....

The black masterbatch has good compatibility with plastic products, so the black masterbatch can stay in the product for a long time and exert its proper performance. However, if the black masterbatch exceeds its compatibility range, it will have a negative impact on the plastic product. For example, when a large ....

First, the difference between masterbatch and toner is shape; the difference in appearance: the masterbatch is granule, and the toner is powder Second, the use of toner and masterbatch is different; toner in the plastic processing uses a professional colorist to do pre-dispersion, color match....

1. Application of film (blow): the use of packaging film (blow) - soft and bright Requirements for color masterbatch: good dispersibility, less impurities, no discoloration. 2. Application in Casting Composite Film: Excellent Plasticity Appearance Flatness, Good mechanical strength. Requirements for maste....

The quality of masterbatch depends mainly on the following five factors. 1. Dispersibility is better. 2. Strong coverage. 3. Liquidity is better. 4. Compatibility is better. 5. Stability should be consistent.....

The production process of black masterbatch is common in the following. (1) Production process of double rotor continuous mixer The production process is to first weigh carbon black, resin and other additives according to the formula, then add the components to a high-speed mixer and mix at normal tempera....

Dedicated color masterbatch: It is a masterbatch made of the same plastic as the carrier according to the plastic type specified by the user for the product. For example, PP color masterbatch and ABS color masterbatch respectively use PP and ABS as carriers. Universal color masterbatch: A resin (often a low melting ....

The agricultural film includes: mulch film, plastic film and agricultural film. The main component is polyethylene, which is used to cover farmland, raise the ground temperature, maintain soil moisture, promote seed germination and rapid growth of seedlings, and inhibit weed growth. The raw material of the agricultur....

The filler masterbatch is a concentrated body prepared by loading a plastic additive into a resin in an extraordinary amount; when manufacturing a plastic product, it is not necessary to add the plastic auxiliary agent, but only the corresponding master batch is added. Thus, the most popular plastic auxiliaries are ....

The masterbatch is generally composed of three parts. The colorant carrier dispersant is kneaded by a high-speed mixer, crushed, and extruded into pellets. The masterbatch has high concentration, good dispersibility and cleanness during plastic processing. And so on. While the pigment is being proces....

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号